- Operating principle

- ACE inhibitors

- Benefit

- Classification and forms

- Application

- Contraindications for treatment with inhibitors

The group of inhibitors includes substances that slow down or completely block chemical (especially enzymatic) and physiological processes.

The name comes from the Latin word inhibere, which means “to capture.” One of the groups - ACE inhibitors - is used to treat pathologies of the cardiovascular system. Among the well-known ACE inhibitors is the drug Enalapril, used for heart failure, essential and renovascular hypertension, as well as for the prevention of the development of pathologies.

Description of inhibitors

What is a corrosion inhibitor? Corrosion inhibitors are special substances that stop (delay) the process of chemical and physical reactions. Corrosion inhibitors occupy a special place among such substances.

Inhibitors include agents that form a special protective film on the metal surface, which is obtained during the reaction of an inhibitor solution and corrosion products.

The emergence of compounds that slow down corrosion processes was a breakthrough. At the moment, most methods of protection are protection using inhibitors. The most popular substances in this capacity are amines, nitrogen-containing substances, urea, sulfides, aldehydes, etc.

The effectiveness of protective processes involving inhibitors directly depends on the metal, the characteristics of the external environment, pressure on the material, etc.

It is worth noting that the corrosion inhibitor protection does not work constantly; when the additive gets into the solution, it gradually dissolves, so in the future it is necessary to add it to an aggressive environment in small portions.

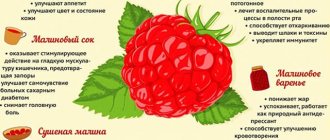

Benefit

ACE inhibitors:

- have an anti-inflammatory effect;

- promote urine excretion;

- increase the sensitivity of peripheral tissues to insulin;

- have a nephroprotective effect, that is, they help preserve kidney function;

- strengthens blood vessels: improves endothelial function, increases the elasticity of walls, is a preventive measure against damage to atherosclerotic plaque;

- prevent an increase in the size of the left ventricle of the heart;

- help to equalize heart rate;

- improve blood circulation in vital systems (parts of the central nervous system, kidneys, heart);

Types and uses of metal corrosion inhibitors

The main types of inhibitors include:

- Cathode – reduce the rate of cathodic interaction.

- Anodic - inhibit the dissolution of the anode.

- Mixed - additives that slow down reactions, both cathodic and anodic.

There is a classification of inhibitors by origin:

- Organic are organic substances that are more versatile because they reduce the rate of cathodic and anodic reactions. These include nitrogen, sulfur, oxygen, and aromatic compounds. The main advantage and difference from inorganic inhibitors is the fact that organic substances are adsorbed only on the surface of the material, without reacting with rust.

- Inorganic corrosion inhibitors, what are they? They contain inorganic substances as part of the inhibitor. The peculiarity of working with inorganic particles in an inhibitor is that if the concentration is incorrectly selected, they may not protect the metal by forming a thin film on it, but rather react with corrosion products and accelerate the destruction process. Includes chromates, sodium and potassium bichromates, calcium bicarbonate, etc.

The principle of action of inhibitors

Classification of inhibitors by mechanism of action

Main types:

- Working in an acidic environment - amines, acetylene alcohols, sulfur-containing compounds, aldehydes. This type of substance is used in the gas and oil production industries; they cover pipelines carrying gas or oil products, as well as products involved in these processes. An acidic environment corrosion inhibitor actively fights cathodic and mixed destruction.

- Inhibitors for neutral environments - phosphates, nitrites, amino acids, chromates, alkylphosphates, sulfonates. They are most widely used in the field of water supply, cooling, and are used on marine vessels. Here, as elsewhere, the inhibitor solution is used as a protective coating for any products of the listed industries, containers, load-bearing structures, and individual elements.

- Occurring in an alkaline environment. The substances are involved in the composition of special detergents. Their action is based on the fact that they reduce the strength of current in its chemical sources. Inhibitors for such purposes are most often used together with cations.

Common Types of Acid Inhibitors

The most economical anti-corrosion inhibitor is acidic. Its consumption in the process of metal etching is minimal, which entails a reduction in the cost of the product and the protection procedure as a whole.

The properties of acid inhibitors can also be supplemented by the fact that when applied to a material, it also cleans it of the formed scales and various oxide films. Also, the additive does not change its properties, is not transformed, and is not destroyed when the ambient temperature increases.

On the domestic market you can most often find such corrosion inhibitors as I-5-V and I-5-VM. These additives are intended for products made of low-carbon, medium-carbon and high-carbon and alloy steels. They are effectively used in industry, and both inhibitors can be combined with each other.

The use of corrosion inhibitors with this composition reduces metal waste, helps clean the surface of the etched material, and also has a beneficial effect on sanitary and hygienic working conditions.

Properties of corrosion inhibitors

All properties of inhibitors are reduced to anti-corrosion protection of metal products. The mechanism of operation is simple: the inhibitor contained in the solution is applied to the surface of the element and protects it from the external influence of aggressive environments. Protection is created by adsorption (increasing the concentration of the inhibitor in the solution and on the surface of the material, respectively) on the metal element. After the appearance of the protective film, its main task is to be completely neutral to external influences, not to change its properties under pressure, temperature, etc., only in this case will the inhibitor be able to fully demonstrate its properties and protect the structure as a whole.

1st generation drugs

The first generation ACE inhibitors were developed in the mid-70s of the last century. Despite their high effectiveness, they are characterized by a large number of side effects. Therefore, it is very important not to deviate from the dosage recommended by the doctor. Using ACE inhibitors on your own, the list of drugs for which is not very large, is strictly prohibited.

Representatives of the first group are the following drugs:

- Captopril. The product guarantees a rapid reduction in blood pressure and is suitable for use in emergency situations. To avoid serious side effects, it can only be used in small doses. This is the only drug that is used to relieve hypertensive crisis.

- Benazepril. The medicine has a milder effect and can be used to correct blood pressure in moderate stage hypertension, as well as in congestive heart failure.

- Zofenopril. The most gentle drug with minimal side effects and antioxidant effect. But at the same time, it is indicated for use only in the initial stages of arterial hypertension.

Cathodic corrosion inhibitor

This type of additive slows down the dissolution of metal during the cathodic process. The system potential moves from its usual neutral state to the negative side, which leads to a decrease in the corrosive current, and an anti-corrosion film is formed on the surface. This film is difficult to dissolve not only under normal conditions, but also for many aggressive environments. It becomes a barrier between the external environment and the metal, maintaining its integrity.

What is cathodic inhibitor corrosion protection? Most often, these are compounds that increase the acidity of the environment, which reduces the possibility of metal dissolution.

Cathode additives are not used in acidic environments, as they are not effective there.

As noted earlier, the inhibitor must be dissolved in some substance before use, the simplest one being water. Experts select the correct concentration of the additive in a given volume of water.

It is worth noting that this type of substance is the least effective in comparison with anodic and mixed inhibitors.

3rd generation drugs

The latest generation of ACE inhibitors are characterized by a mild effect and minimal side effects. But at the same time, the result after administration occurs no earlier than 30-60 minutes, which is not always acceptable.

3rd generation drugs include fosinopril and ceronapril. These products are equivalent in their effects and are often prescribed for long-term use. Moreover, the effect after administration lasts for a long time. Medicines are not suitable for emergency situations.

Anodic corrosion inhibitors

These substances are passivators - substances that pass from an active state to a passive state and form a film. This film protects the metal element. Corrosion slows down due to a decrease in the rate of transition of metal ions into the solution, and the area of the anodic areas covered with the film decreases due to their separation.

It is the anodic additives, if you overdo them, that may not reduce, but accelerate the corrosive destruction of the material. Carbonates, silicates, phosphates, and sodium nitrite are popular as anodic corrosion inhibitors.

Application of inhibitors in the oil and gas industry

Oil and gas are quite aggressive environments, as they contain caustic substances that can corrode materials and adversely affect human health. Based on this, special additives for the protection of metal structures are used at any stage of oil and gas production, transportation, storage and operation. An important aspect is that it is advisable to use the same inhibitor at all these stages.

In addition to protecting the metal, impurities can be added to the petroleum products themselves, which make it a less aggressive environment: anti-corrosion paraffin inhibitors, anti-ignition agents and anti-foaming agents. The most common substance for protecting main oil and gas pipelines is amine-based compounds.

Use of inhibitors at home

Corrosion processes affect not only metal products in industrial and construction industries, but also any metal products in our home, as well as machines and devices.

The simplest home remedy with an inhibitor is a primer. As always, the surface must be prepared and then primed with a spatula or brush. The primer creates a protective layer on the product, separating the metal and the environment.

Some paint coatings also contain inhibitors.

The simplest and most understandable inhibitors for household use are minium (red lead paint) added to the primer, iron or zinc orthophosphates added to the solution, etc.

Red lead paint

The use of inhibitors when processing equipment

Corrosion in technology is the greatest threat to human life. Often, a corroded area in a large member is not as bad as corrosion in a bolted joint or weld.

Most often, of course, car owners are faced with the problem of rust and take their cars to a service station so that the specialists themselves can process the material and apply an anti-corrosion coating, whether using inhibitors or not.

The destruction of equipment is difficult to stop, since areas susceptible to destruction are usually difficult to access, treatment with a corrosion inhibitor, and cleaning the affected area is difficult. In inaccessible places, they try to use liquid compounds for better application and distribution - oils, hot bitumen compounds, soft lubricants, etc.

Side effects

Serious side effects while taking ATP inhibitors occur most often during treatment with first-generation drugs. In most cases, there is dizziness, which can cause fainting. Sometimes nausea, vomiting, stool upset and various other dyspeptic symptoms occur.

If the prescribed dosage is exceeded, there is a sharp decrease in blood pressure below normal, problems with kidney function or hyperkalemia. While taking ACE inhibitors of any generation, a dry cough or allergic reactions may occur. Very rarely, cases of angioedema have been reported with monotherapy. If such symptoms appear, you should immediately consult a doctor.